Gently Deflected

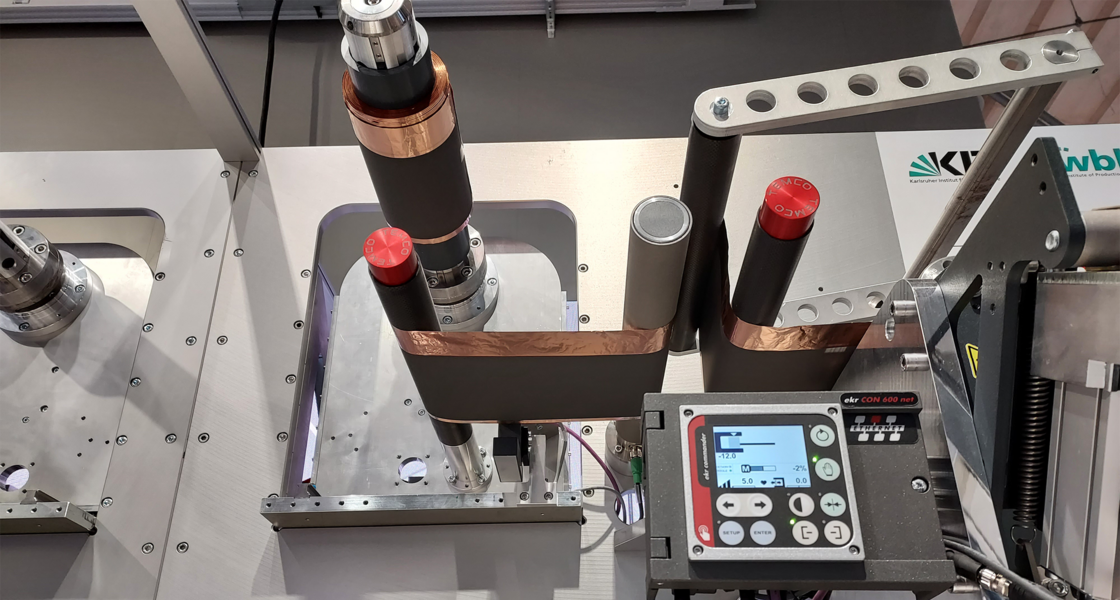

Driven by new technologies, the battery industry is rapidly growing. With deflection resp. idler rollers from Temco, customers are well equipped for the production of the cell types of the future, such as the all-solid-state or lithium-air battery as well as lithium ion batteries. The production of the lithium batteries require special conditions, especially in the deflection process. To prevent the fine foils from tearing or being damaged in any other way, the transport must be particularly smooth and the rollers used must be especially precise. Whether for round, pouch or prismatic cells, the components cover the deflection processes of coating, drying, calendering, slitting, separating, stacking and winding.